The most prominent sustainability trend is the rapid phase-out of Sulfur Hexafluoride (SF6) gas. For decades, SF6 has been the standard insulating and arc-quenching medium in high and medium-voltage gas-insulated switchgear (GIS) due to its outstanding electrical properties. However, SF6 is the most potent greenhouse gas known, with a global warming potential 23,500 times that of CO2. The environmental contradiction of using such a gas in infrastructure supporting renewable energy has become untenable. The industry's response has been the accelerated development and deployment of SF6-free switchgear alternatives. These solutions primarily utilize vacuum interruption technology for circuit breaking, paired with environmentally benign insulating gases such as clean air (a nitrogen-oxygen mixture) or dry air. This shift represents a critical step in creating a truly sustainable and eco-friendly power infrastructure, aligning the substation's operation with the green goals of the energy it transmits.

Alongside the gas transition, there is a strong focus on improving the energy efficiency of substation assets. Power transformers, while highly efficient, still represent a source of continuous energy loss 24/7. The adoption of amorphous metal core transformers can reduce no-load losses by up to 70% compared to traditional silicon-steel cores. While the initial cost is higher, the total cost of ownership and the reduction in carbon emissions over the transformer's 25-30 year life make it a compelling sustainable choice. Similarly, the use of low-loss, high-efficiency distribution transformers at the secondary level further compounds these energy savings across the grid.

The second major driver, resilience, is being addressed through both physical and cyber hardening. Physically, modern substation equipment is designed to withstand more extreme environmental conditions. This includes seismic-rated equipment for earthquake-prone regions, submersible transformers and switchgear for areas susceptible to flooding, and corrosion-resistant coatings and materials for coastal installations. This enhanced ruggedization ensures that the substation remains operational—or can be restored quickly—following severe weather events, which are increasing in frequency and intensity.

Cybersecurity has become a non-negotiable aspect of resilience. As substations become more digital and connected, they become potential targets for malicious cyberattacks that could disrupt the power supply. Consequently, modern IEDs and communication gateways are now built with embedded cybersecurity features. These include secure boot mechanisms, role-based access control, and support for encrypted communication protocols to prevent unauthorized access and data manipulation. The concept of a "cyber-hardened substation" involves designing the entire digital ecosystem with security as a core principle, not an afterthought, ensuring the integrity of the grid's control systems.

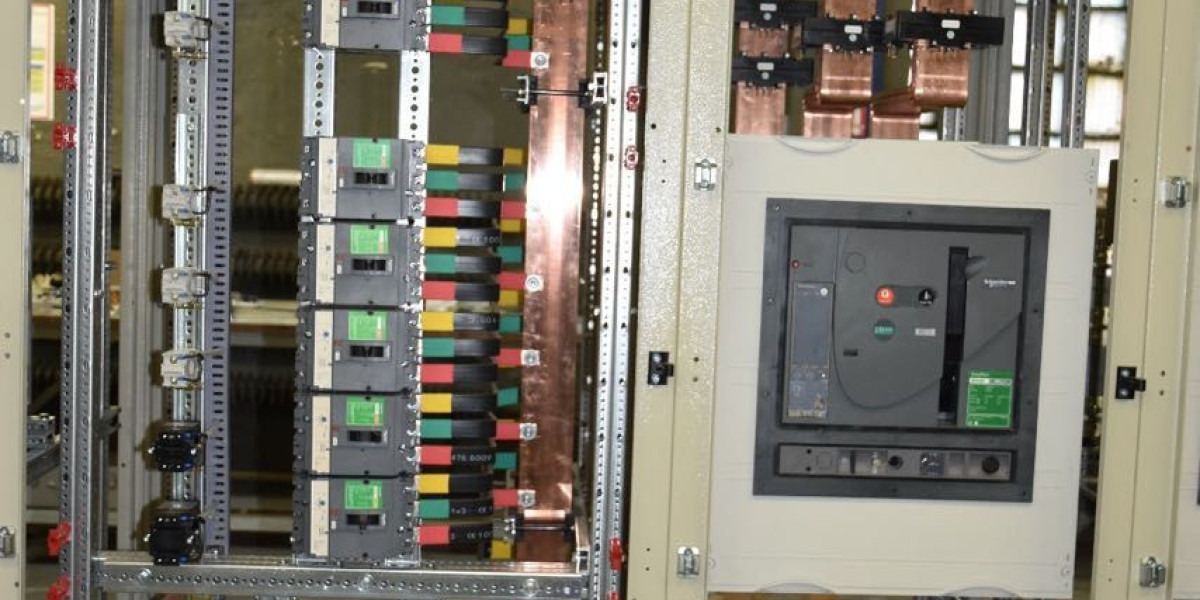

Finally, the concept of modular and compact substation designs is gaining traction for enhancing both speed of deployment and resilience. Prefabricated, containerized substations can be manufactured off-site and rapidly deployed in the field, slashing project timelines. This modularity also aids in resilience; if a section is damaged, it can be isolated and replaced quickly. These designs often utilize gas-insulated switchgear (GIS) or its SF6-free successors, which have a much smaller footprint than traditional air-insulated switchgear (AIS), making them ideal for space-constrained urban environments.

In conclusion, the development of modern substation equipment is a direct response to the macro challenges of our time. It is an exercise in building infrastructure that is not only more intelligent but also more responsible and robust. The integration of SF6-free technology, high-efficiency assets, and cyber-secure, hardened designs defines the path forward. For utilities, this means carefully selecting partners who are committed to these principles. Manufacturers like Degatech Electric are actively contributing to this future with their focus on sustainable switchgear solutions and resilient electrical equipment. By prioritizing these advanced components, the industry can build a grid that is prepared to meet the demands of the 21st century—a grid that is clean, dependable, and secure.