In today’s competitive engineering and manufacturing landscape, innovation and precision are crucial for creating reliable products while reducing time-to-market and costs. Computer-Aided Design (CAD) and Finite Element Analysis (FEA) have become indispensable tools for engineers, designers, and product developers. Together, they streamline the process of designing, testing, and validating products before physical prototypes are built, ultimately enhancing efficiency, accuracy, and innovation.

Understanding CAD (Computer-Aided Design)

CAD refers to the use of software applications to create, modify, analyze, or optimize a design. It allows engineers to build digital models of components, assemblies, or entire systems in two-dimensional (2D) or three-dimensional (3D) environments. Unlike traditional hand-drawn blueprints, CAD models are more detailed, accurate, and flexible.

Modern CAD software provides features such as parametric modeling, direct modeling, surface modeling, and assembly management. Engineers can create highly complex geometries, simulate movement, and visualize how components interact within a system. This digital environment reduces errors, improves collaboration, and supports faster design iterations.

Key Benefits of CAD:

Accuracy: CAD eliminates human errors found in manual drafting, producing precise dimensions and tolerances.

Visualization: 3D modeling provides a realistic view of the final product before manufacturing.

Flexibility: Changes can be implemented quickly and easily without starting from scratch.

Collaboration: CAD files can be shared across teams, making remote or cross-disciplinary work seamless.

Documentation: CAD automates the creation of drawings, bills of materials (BOM), and assembly instructions.

Popular CAD software includes AutoCAD, SolidWorks, CATIA, Siemens NX, and PTC Creo, each offering specialized tools for different industries like automotive, aerospace, consumer products, and industrial machinery.

Understanding FEA (Finite Element Analysis)

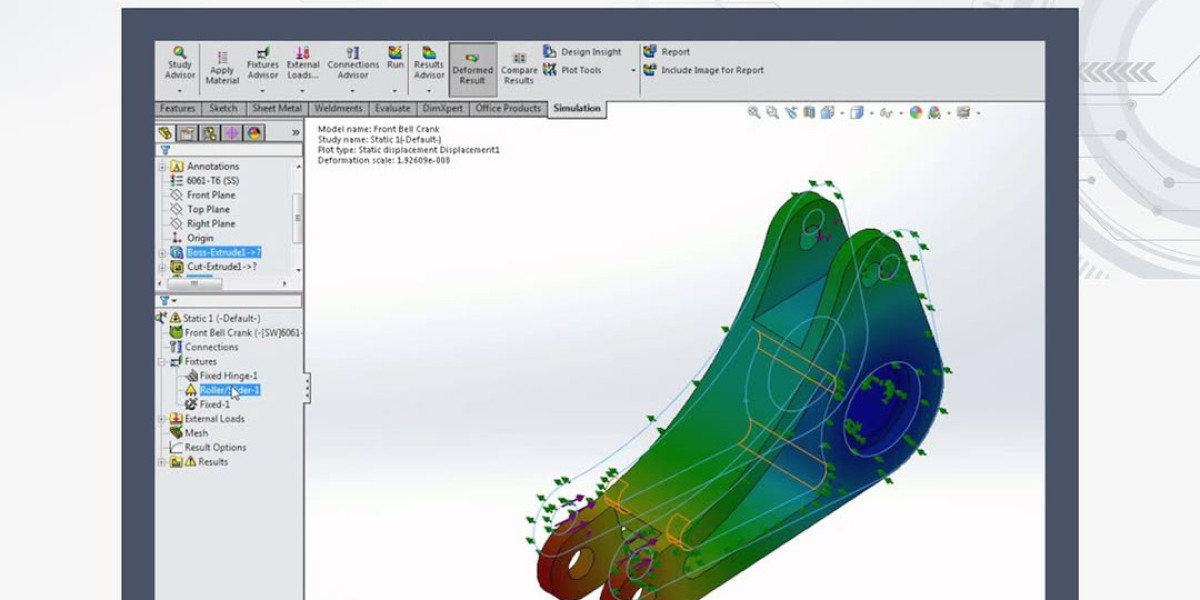

FEA is a computational technique used to predict how a product or structure will react under real-world conditions such as force, heat, vibration, and other physical effects. Instead of creating multiple prototypes and testing them physically, engineers use FEA simulations to evaluate performance at the design stage.

The process involves dividing a complex structure into small, finite elements connected at nodes. Mathematical equations describe how each element behaves, and the results are combined to predict the overall behavior of the product.

Common Applications of FEA:

Structural Analysis: Evaluating stresses, strains, and deformations in components under load.

Thermal Analysis: Studying heat distribution, thermal stresses, and cooling requirements.

Vibration and Modal Analysis: Identifying natural frequencies and resonant conditions.

Fatigue Analysis: Estimating product lifespan under repeated loading conditions.

Fluid-Structure Interaction: Assessing how fluids and structures affect each other in dynamic systems.

Advantages of FEA:

Reduces the need for costly physical prototypes.

Identifies design weaknesses early in the development process.

Provides insights into product safety and compliance with standards.

Enables optimization of material usage, reducing waste and cost.

Popular FEA software packages include ANSYS, Abaqus, COMSOL Multiphysics, and Nastran. Many CAD platforms also integrate FEA modules, allowing seamless transition from design to analysis.

CAD and FEA Integration

The real power lies in integrating CAD and FEA into a unified workflow. Instead of treating design and analysis as separate stages, modern engineering tools allow designers to run simulations directly on CAD models. This integration leads to faster feedback loops, better design optimization, and a more collaborative product development environment.

For example, an automotive engineer designing a suspension component can create the CAD model, run FEA simulations to test stress and fatigue under road conditions, and refine the design iteratively—all within a single platform. This not only accelerates development but also ensures a high degree of reliability and safety before physical production.

Applications Across Industries

The versatility of CAD/FEA design and analysis makes it applicable across a wide range of industries:

Automotive: Designing lightweight yet durable components, improving crash safety, and optimizing aerodynamics.

Aerospace: Ensuring structural integrity of aircraft parts under extreme conditions while minimizing weight.

Civil Engineering: Analyzing bridges, buildings, and infrastructure for load-bearing capacity and safety.

Consumer Products: Enhancing ergonomics, durability, and performance of everyday items like electronics or appliances.

Energy Sector: Studying turbine blades, pipelines, and renewable energy systems under various stresses and thermal conditions.

Future Trends in CAD/FEA

The future of CAD/FEA design and analysis is being shaped by advancements in digital technologies:

Artificial Intelligence (AI) and Machine Learning: AI-driven design optimization will help engineers explore more design possibilities quickly.

Cloud-Based Solutions: Cloud CAD/FEA platforms enable collaboration across the globe, offering scalable computing resources.

Generative Design: CAD systems now use algorithms to generate multiple design alternatives based on performance criteria, which can then be validated using FEA.

Digital Twins: Real-time simulation models that replicate physical systems will allow continuous monitoring and predictive maintenance.

Additive Manufacturing Integration: CAD/FEA tools are increasingly optimized for 3D printing, ensuring that parts are not only printable but also structurally sound.

Conclusion

CAD and FEA have revolutionized the way products are designed, tested, and manufactured. CAD provides the creative and precise modeling environment, while FEA delivers powerful analysis to validate and optimize designs. When integrated, these tools minimize risks, save costs, accelerate innovation, and improve product performance.

As industries move towards smarter, faster, and more sustainable development practices, CAD/FEA design and analysis will continue to be at the core of engineering innovation. Organizations that embrace these technologies are better equipped to stay ahead in a rapidly evolving marketplace, ensuring their products meet both functional requirements and customer expectations with confidence.