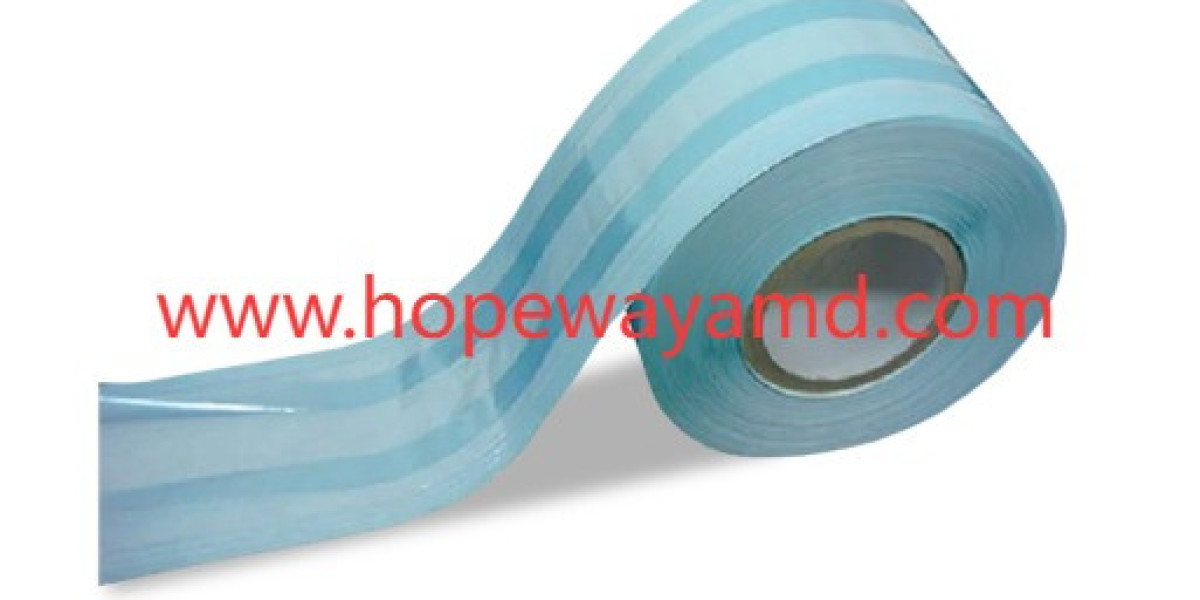

Maintaining a secure and sterile barrier is critical in medical and laboratory operations, and the Sterilization Gusseted Roll produced by Hopewayamd provides a dependable solution that aligns with regulated handling procedures. Designed for use in clean environments, this roll format is tailored for packing bulkier or irregular-shaped instruments while ensuring a uniform seal and integrity across its surfaces.

The gusseted design allows for dimensional flexibility, offering additional space without compromising the sterility of enclosed items. This is particularly valuable in healthcare settings where tool kits and surgical sets vary in shape and volume. The structure promotes even airflow during sterilization cycles, reducing pockets of resistance and improving overall effectiveness of the process.

In production lines and sterile storage rooms alike, the consistency of materials plays a vital role. A gusseted roll must perform under diverse temperature and humidity conditions, and it must be compatible with common sterilization techniques such as steam or ethylene oxide. A reliable roll allows staff to focus on process precision, not packaging inconsistencies.

Ease of use is another strength. The material unwinds smoothly and holds shape during loading, which supports efficiency during high-volume preparation. Sealing edges remain intact under pressure and transit, reinforcing the sterility of contents until the point of use. These design considerations help minimize risks during both storage and distribution.

Choosing the right packaging medium isn't just about fit—it's about function. When your application calls for assurance in both structure and sterilization, make sure your materials meet the mark. Step forward with confidence by visiting https://www.hopewayamd.com/news/industry-news/hopewayamd-sterilization-gusseted-roll-barrier-sustainability.html where purposeful packaging begins with thoughtful design. Let the right tools quietly elevate your sterilization process.