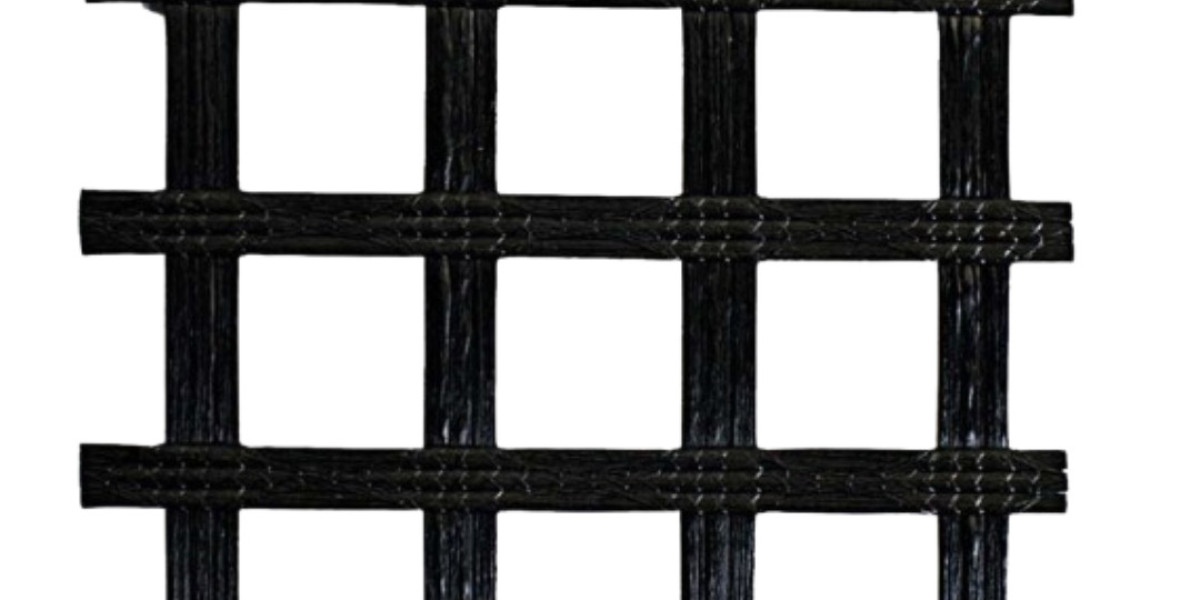

One such innovation is the use of uniaxial geogrids, which have become a crucial element in various engineering projects. These geogrids provide exceptional strength, durability, and stability to structures by reinforcing soil and improving load-bearing capacities.

Uniaxial geogrids are specialized geosynthetic materials designed primarily for applications requiring high tensile strength in a single direction. These Uniaxial geogrid exporters in Ahmedabadare used extensively in retaining walls, steep slopes, embankments, and other structures requiring soil stabilization. Their robust design and superior engineering make them ideal for enhancing the performance of infrastructure projects.

The Role of Uniaxial Geogrids in Infrastructure Development

Infrastructure projects, such as roadways, bridges, and embankments, demand materials that ensure long-term stability and load-bearing efficiency. Uniaxial geogrids play a vital role in meeting these requirements by preventing soil movement and distributing loads effectively.

The key functions of uniaxial geogrids include:

Reinforcing weak soil and preventing erosion

Enhancing the bearing capacity of retaining walls

Reducing settlement in embankments and foundations

Allowing for the construction of steeper slopes with increased stability

By incorporating these geogrids into construction projects, engineers can significantly improve the overall strength and durability of structures while minimizing maintenance costs.

Manufacturing Excellence in Ahmedabad

Uniaxial geogrid manufacturers in Ahmedabad are known for producing high-quality geosynthetic solutions that meet international standards. These manufacturers utilize state-of-the-art technology and innovative production techniques to develop geogrids that withstand extreme environmental conditions and heavy loads.

The manufacturing process involves:

Selecting high-grade polymer materials such as high-density polyethylene (HDPE) and polypropylene

Using advanced extrusion and stretching techniques to ensure optimal tensile strength

Conducting rigorous quality control tests to meet industry specifications

These manufacturers cater to both domestic and international markets, offering reliable solutions for various construction applications.

Global Reach: Exporting Uniaxial Geogrids from Ahmedabad

Uniaxial geogrid exporters in Ahmedabad have successfully positioned themselves as global suppliers of durable geosynthetic materials. By adhering to stringent quality standards and ensuring efficient logistics, these exporters provide high-performance Uniaxial geogrid manufacturers in Ahmedabadto clients across various countries.

The export process involves:

Compliance with international quality certifications

Customization of geogrids based on specific project requirements

Timely delivery and efficient supply chain management

With a growing demand for sustainable construction solutions, exporters in Ahmedabad continue to expand their reach, supplying geogrids for large-scale infrastructure developments worldwide.

Uniaxial Geogrid Exporters : Strengthening Global Infrastructure

India has emerged as a key player in the global geosynthetics market, with several manufacturers and exporters specializing in uniaxial geogrids. Uniaxial geogrid exporters in India offer high-performance solutions that contribute to the success of various construction projects, including highways, railways, and mining operations.

Indian exporters have established a strong reputation by:

Offering cost-effective and durable geogrid solutions

Meeting international engineering standards

Ensuring eco-friendly and sustainable manufacturing processes

Their commitment to quality and innovation has positioned India as a preferred supplier of uniaxial geogrids for infrastructure projects worldwide.

Advantages of Using Uniaxial Geogrids

Uniaxial geogrids offer numerous benefits that make them indispensable in modern construction. Some of the key advantages include:

Enhanced Soil Stability: These geogrids provide excellent soil reinforcement, preventing shifting and displacement.

Increased Load-Bearing Capacity: By distributing loads efficiently, they improve the durability of structures.

Cost-Effective Construction: The use of geogrids reduces the need for additional soil excavation and replacement, lowering overall project costs.

Eco-Friendly Solution: Made from recyclable materials, uniaxial geogrids promote sustainable construction practices.

Easy Installation: Their lightweight and flexible design allow for quick and hassle-free installation.

Conclusion

Uniaxial geogrids have become an essential component in modern construction, ensuring the stability and longevity of various infrastructure projects. With a strong manufacturing base in Ahmedabad and a growing presence in international markets Uniaxial geogrid exporters in Indiaand across India are playing a pivotal role in enhancing global construction standards. Their commitment to quality, innovation, and sustainability makes them a reliable choice for engineering applications worldwide.

As the demand for robust and efficient soil reinforcement solutions continues to rise, uniaxial geogrids will remain a cornerstone of structural integrity, providing engineers with the necessary tools to build resilient and long-lasting infrastructure.

Frequently Asked Questions (FAQs)

What are the primary applications of uniaxial geogrids?

Uniaxial geogrids are primarily used in soil reinforcement applications such as retaining walls, steep slopes, embankments, bridge abutments, and roadway construction. They help in stabilizing soil and enhancing the load-bearing capacity of structures.How do uniaxial geogrids improve construction efficiency?

By reinforcing weak soil, uniaxial geogrids reduce the need for extensive excavation and soil replacement, leading to cost savings. They also improve the longevity of structures by preventing soil movement and settlement.Why are uniaxial geogrids preferred over other reinforcement materials?

Uniaxial geogrids offer superior tensile strength, long-term durability, and resistance to environmental factors such as moisture and chemicals. Their lightweight nature and ease of installation make them a preferred choice for engineers and contractors.